Overview the visual inspection antomation system

Base ideas to invent system

- Semiconductor process line: measure distance; inspect scratch, chip, mark, confusion,...

- Automobile parts process line: measure distance, inspect welding seam,...

- Pharmacy process line: Inspect label, packaging status, drug's color,...

- This system can be applied to any industrial process line you want to inspect appearance of products as defect below.

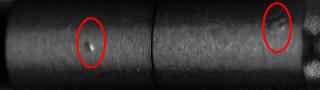

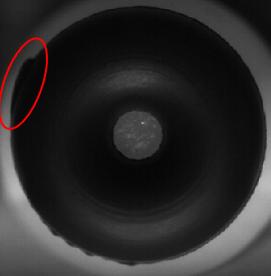

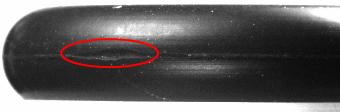

Some images errors that the system has detected:

Semi-conductor product

Resin pilot

O-ring

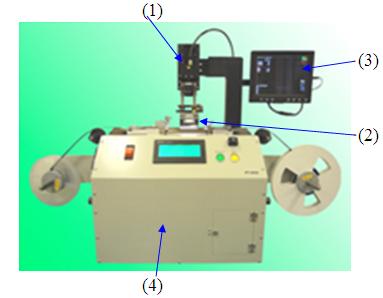

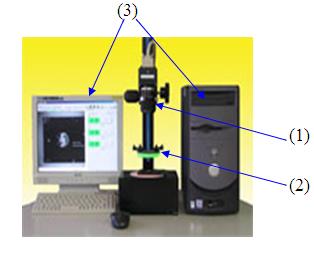

Basic Construction

Inspection unit

(2) Lighting: support for capture image clearly

(3) Computer and monitor: Process image and display inspection result

Supplying and sorting Unit (Mechanics and Control)

(4) Supply and sort products according to inspection result.

Basic operation of the system

Supplying Unit move product to under camera. Camera captures the image of product then input into computer.

Image is processed, analysed by software for inspecting and output the inspection result to sorting uint.

Product will be sorted according to inspection result.

Image is processed, analysed by software for inspecting and output the inspection result to sorting uint.

Product will be sorted according to inspection result.