Multipurpose Vision Inspection Unit - MVI250

With this inspection unit, you can set to inspect for any product you want to detect error of surface and distance.

General function of inspection software

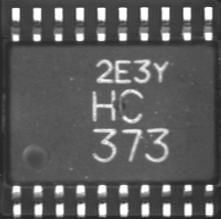

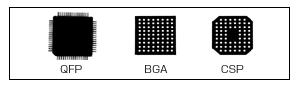

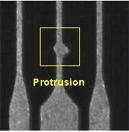

Semi-Conductor process

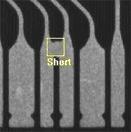

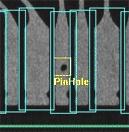

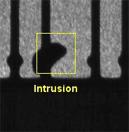

Inspecting surface (for SOP, TSSOP)

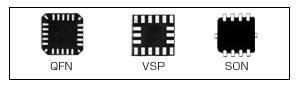

Inspecting back face (for QFN/VSP/SON)

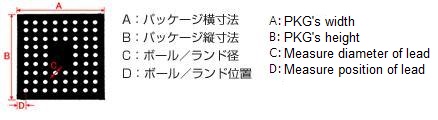

Inspecting back face (For BGA/CSP/LGA)

Inspecting board circuit

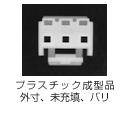

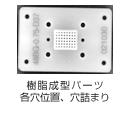

Inspecting other products

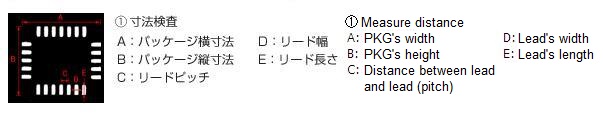

Measure distance

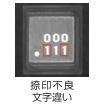

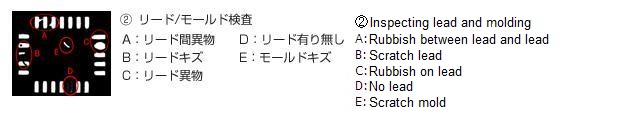

Inspecting rubbish

360 ° crush

Rubbish

Measure distance, rubbish

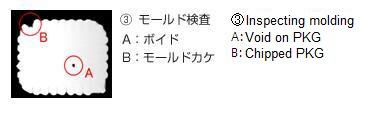

Immature mold

Inspecting holes

Measure distance,

Rubbish

360 ° scratch, chipped

Rubbish

Using Hint

For customers are production companies

- Improve old visual inspection machine. You have visual inspection machine with using old technology. It does not satisfy current production needs in productivity and quality. You can improve this machine by replacing old vision unit with our MV250 vision unit. It is very simple way by just connecting IO communication between older machine and MVI250 unit. It is a economical and effective method.

- Use to measure distance of sample and save measurement data in a electronic file. You just put the sample on inspection stage under camera and press the test button. MVI250 Unit will measure sample and save the data automatically.

- Use as semi-automatic inspection machine If you need to inspect product without automation, you only need a operator put product on inspection stage under camera. System will capture image of product and inspect automatically, then display the inspection result on the screen, save the result data to the computer. It is a economical and effective method, too.

- Complete visual inspection automation machine. You need an automation inspection machine, we are willing to design, manufacture and transfer in package.

For customers are manufacturing machine companies.

- Using vision unit MVI250. You can use vision unit MVI250 connecting IO communication with your control unit. So, complete visual inspection automation machine will be created.

- Co-operation manufacture If you need to manufacture a visual inspection automation machine. Please contact us without hesitate. We are willing to share this technology to impulse the development of industrial automation in Vietnam

Some production lines have used this vision Unit.

- Use in visual inspection automation machine for semi-condictor process.

- Use in robot for alignment position of device.

- Use in visual inspection automation machine for automobile parts process.

- Use in visual inspection automation machine for inspecting O-ring.